- OUR PRODUCTION

We specialize in the following sectors:

Automotive - Agricultural - Trucks - Earthmoving Machinery

SCF srl, with extensive experience in the hot steel forging sector and thanks to continuous investments aimed at renewing and enhancing its plant and machinery, is able to offer its customers high-quality products with fast delivery times, while maintaining competitiveness through the remarkable versatility of its operations.

The company’s main products include gears, flanges, bushings, and hubs, primarily serving the automotive, agricultural, and earthmoving machinery sectors.

Our components are installed on the following brands: Mercedes, Iveco, Volvo, Scania, CAT, and FPT.

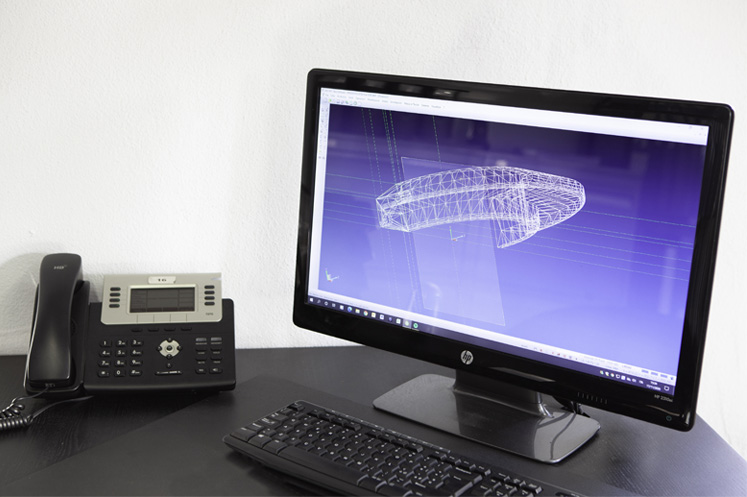

Design

Visi Modelling

Thanks to a powerful solid and surface modeling software,

we are able to carry out the complete creation of 3D models needed for the production of any part we intend to forge.

Tooling

Die Manufacturing

SCF srl is directly involved in the design and manufacturing of dies.

This phase, carried out in-house, offers the advantage of being able to act quickly on the die production should any changes arise during the process.

Forging

Hot Forging

The hot forging department is equipped with 3 lines featuring Vaccari and Dellavia screw presses of 400, 800, and 1600 tons, served by “CEFI” induction furnaces ranging from 400 to 800 kW. It manufactures components for the automotive, agricultural, and earthmoving machinery industries. All forging lines are also equipped with mechanical presses for flash trimming of the forged components.

Cutting

Lines

We are equipped with machines for billet cutting.

With a view to providing a complete production cycle, SCF has invested in disc cutting machines

to meet its customers’ needs and offer finished products quickly.

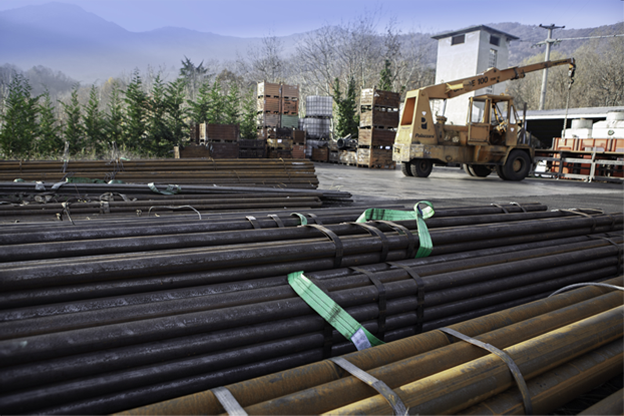

Raw Material

Storage

SCF srl, always attentive to the high quality of products and materials,

uses only top-quality raw materials sourced from the best certified Italian steel mills.

The company is also capable of storing large quantities of material on-site, ready for processing.

All materials undergo the most rigorous quality checks and are stored in designated areas for immediate identification and efficient use.

Heat Treatment

and Sandblasting

At the end of the production cycle, SCF is able to provide heat treatment and sandblasting services for the forged product. SCF srl therefore positions itself in the hot forging market as a single, reliable, and competitive point of contact.

- WE ARE AT YOUR SERVICE, CONTACT US